Description

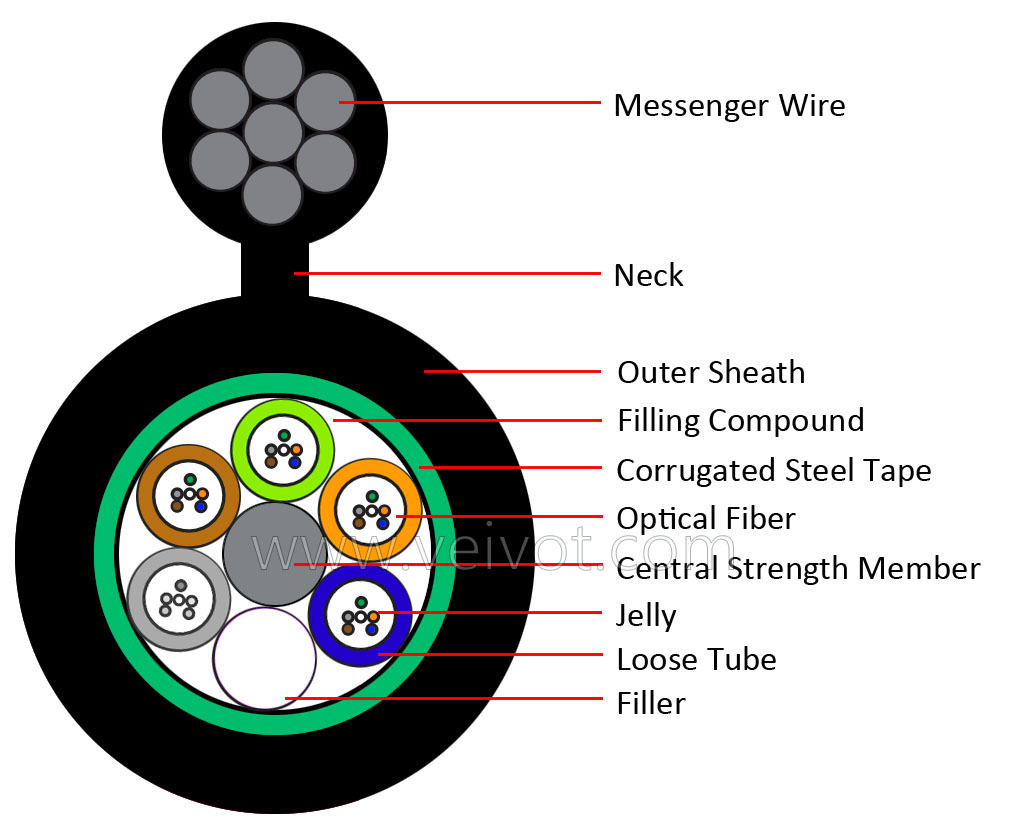

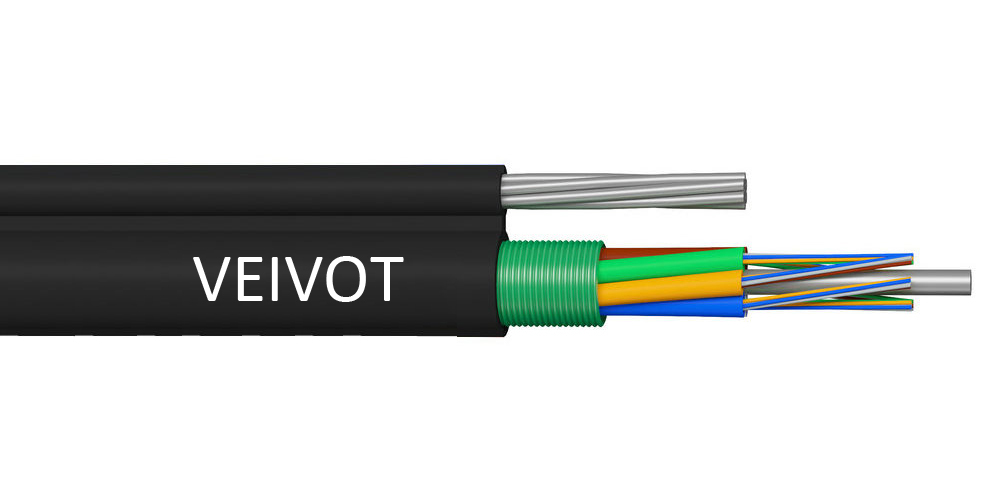

The structure of GYTC8S optical cable is to insert 250 μm optical fibera into a loose tube made of high modulus plastic, and fill the loose tube with waterproof compound. The center of the cable core is a metal center strength member, and the loose tubes (and filling ropes) are stranded around the center strength member to form a compact and circular cable core. After the cable core is longitudinally wrapped with plastic coated corrugated steel tape, it is integrated with the stranded steel wires strand, extrused the polyethylene sheath to be figure8 structure.

Features

Fiber counts: 4 ~ 144 fibers

Fiber Type: G652D; G657A1; G657A2; G655C; OM1; OM2; OM3; OM4; OM5

Outer jacket: MDPE; HDPE

Excellent mechanical and temperature properties are guaranteed by precise excess fibers.

The key protection of fiber is based on excellent hydrolysis resistance.

It has excellent compression resistance and flexibility.

Corrugated steel tape enhances the compression resistance, impact resistance, and moisture resistance of the cable.

It has good UV resistance, PE sheath, and easy installation.

Application

Outdoor aerial

Standard

YD/T 1155-2001

IEC 60794-1

TIA/EIA 598 A

Structure parameters of optical cable

Item | Contents | Unit | Parameters | ||||||

Optical Fiber | Count | / | 6 | 12 | 24 | 36 | 48 | 72 | 96 |

Cable Structure | / | / | 1+5 | 1+6 | 1+8 | ||||

Loose Tube | Each Tube Fiber Count | / | 6 | 12 | |||||

Count | / | 1 | 2 | 4 | 3 | 4 | 6 | 8 | |

Material | / | PBT | |||||||

Filler | Count | / | 4 | 3 | 1 | 2 | 1 | 0 | 0 |

CSM | Material | / | Steel Wire | ||||||

Water Blocking | Material | / | Filling Compound | ||||||

Armor | Material | / | Corrugated Steel Tape | ||||||

Outer Jacket | Material | / | PE | ||||||

Color | / | Black | |||||||

Messenger | Material | / | Steel Wire | ||||||

Wire Diameter | mm | 1.0mm*7 | |||||||

Thickness | mm | 1.0 | |||||||

Diameter | mm | 5.0 | |||||||

Cable Diameter | ±0.5 | mm | 8.9*15.9 | 9.5*16.5 | 10.0*17.0 | 11.2*18.2 | |||

Cable Weight | ±10% | kg/km | 153 | 162 | 179 | 194 | |||

Mechanical & Environmental Performance

Item | Contents | Unit | Parameters |

Max. Tensile Strength | Short term | N | 1500 |

Long term | N | 600 | |

Max. Crush | Short term | N/100mm | 1000 |

Long term | N/100mm | 300 | |

Min. Bending Radius | Operation | mm | 10 times of cable diameter |

Installation | mm | 20 times of cable diameter | |

Applicable Temperature Range | Operation | ℃ | -40 ~ +70 |

Installation | ℃ | -20 ~ +60 | |

Storage & Shipping | ℃ | -40 ~ +70 |

INQUIRY

INQUIRY