Description

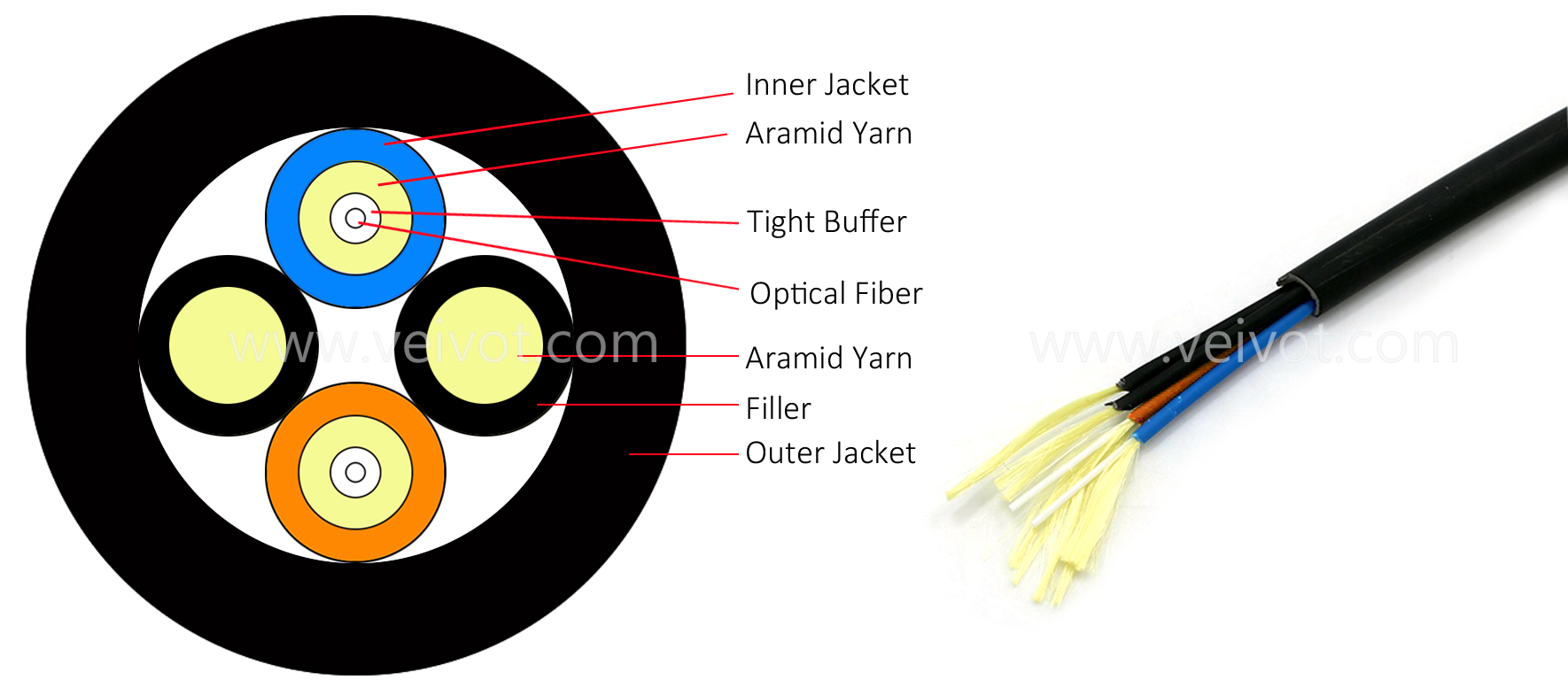

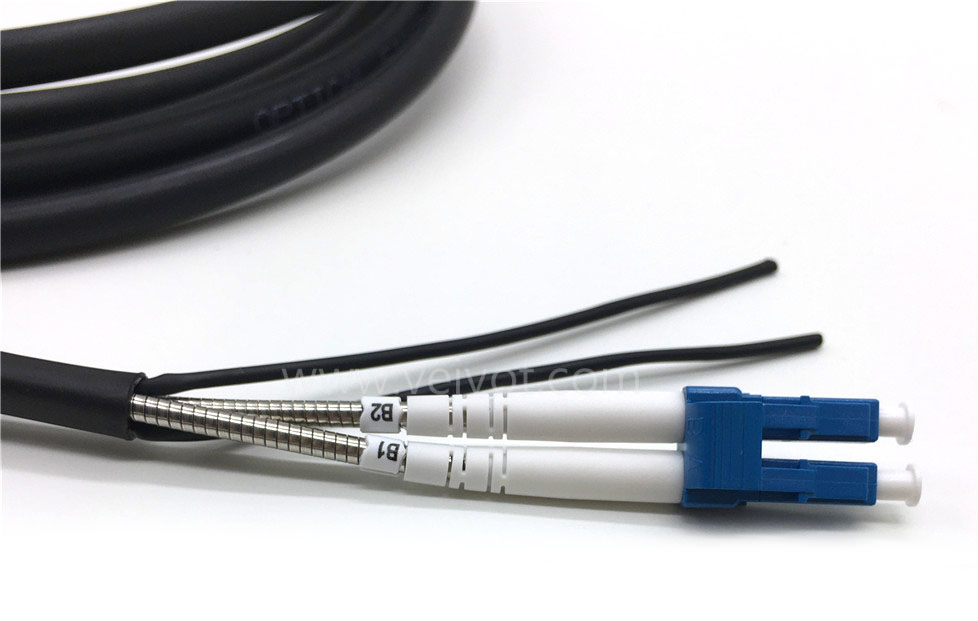

VEIVOT GYFJH 1-4 cores Far Transmission Optical Fiber Cable is designed for Outdoor Base Station Construction. GYFJH optical Fiber cable adopts branchable structure design, convenient construction, compact optical cable structure, small outer diameter, light weight, small bending radius, and excellent mechanical properties.

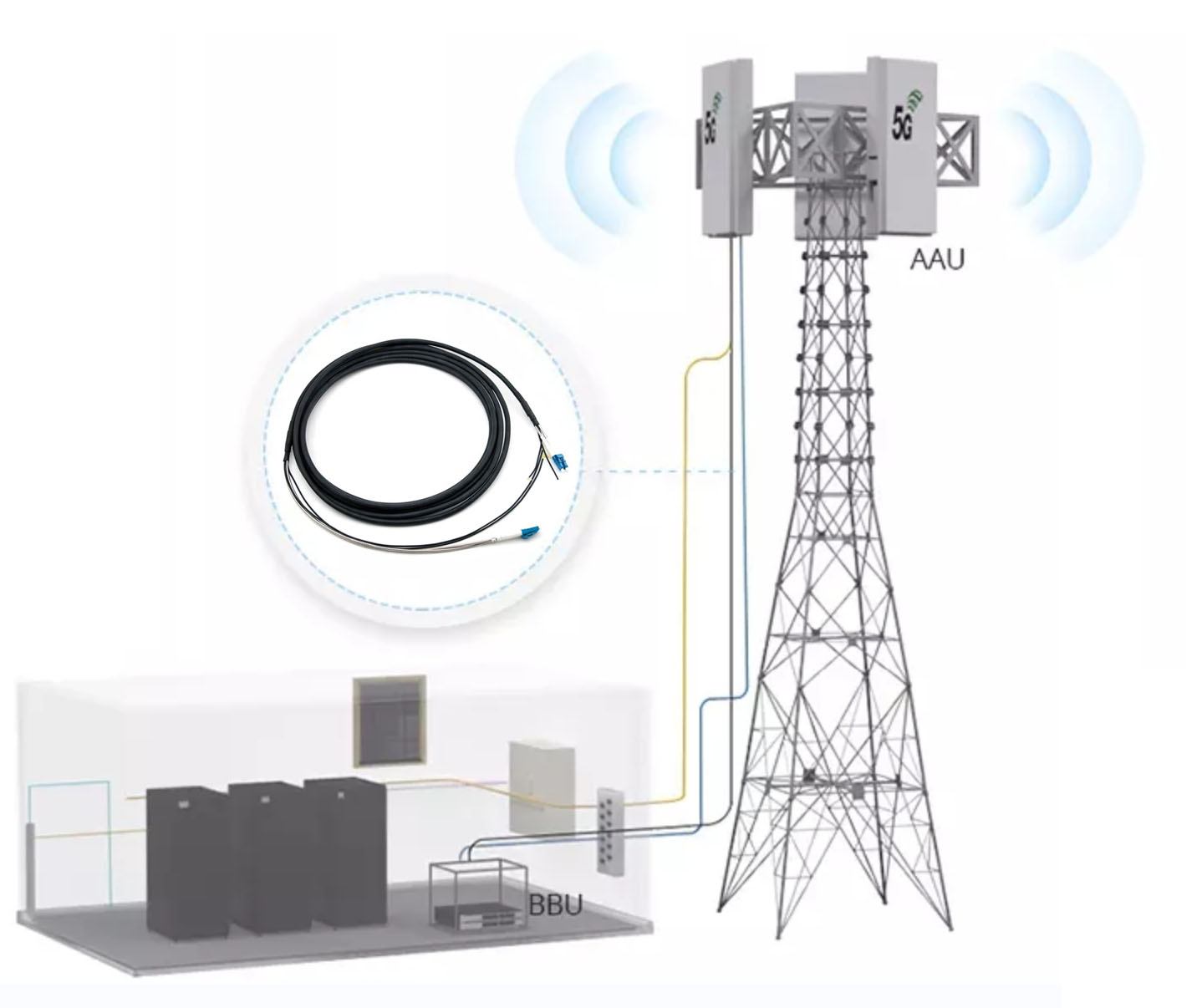

This type of specialized fiber patch cable is designed for harsh environment application such ashigh performance fiber-to-the antenna (FTTA) cabling for current 4G/LTE and 5G network and basestation construction connecting AAU and RRU, also suitable for wireless horizontal and vertical cabling in indoorloutdoor environment.

Feature

High-strength aramid reinforcement to ensure long-term stability of fiber optic transmission characteristics;

Easy to build and maintain;

Each unit cable contains individual reinforcement elements;

Each unit cable can be directly terminated with a standard connector;

LSZH flame retardant material is used to meet the performance requirements of flame retardant and environmental protection for indoor use of fiber optic cable.

Optical Fiber Characteristics

Standard ITU-T G.657A

Items | Unit | Specification | ||

Before cabled | After cabled | |||

Mode Field Diameter | 1310nm | μm | 8.6±0.4 | |

1550nm | 9.8±0.5 | |||

Cladding Diameter | μm | 125.0±0.7 | ||

Cladding Non-Circularity | % | ≤0.8 | ||

Core-Cladding Concentricity Error | μm | ≤0.6 | ||

Coating Diameter | μm | 247±5 | ||

Coating Non-Circularity | % | ≤6.0 | ||

Cladding-Coating Concentricity Error | μm | <12.0 | ||

Cable Cutoff Wavelength | nm | λcc≤1260 | ||

Attenuation(max.) | 1310nm | dB/km | ≤0.35 | ≤0.36 |

1550nm | ≤0.21 | ≤0.24 | ||

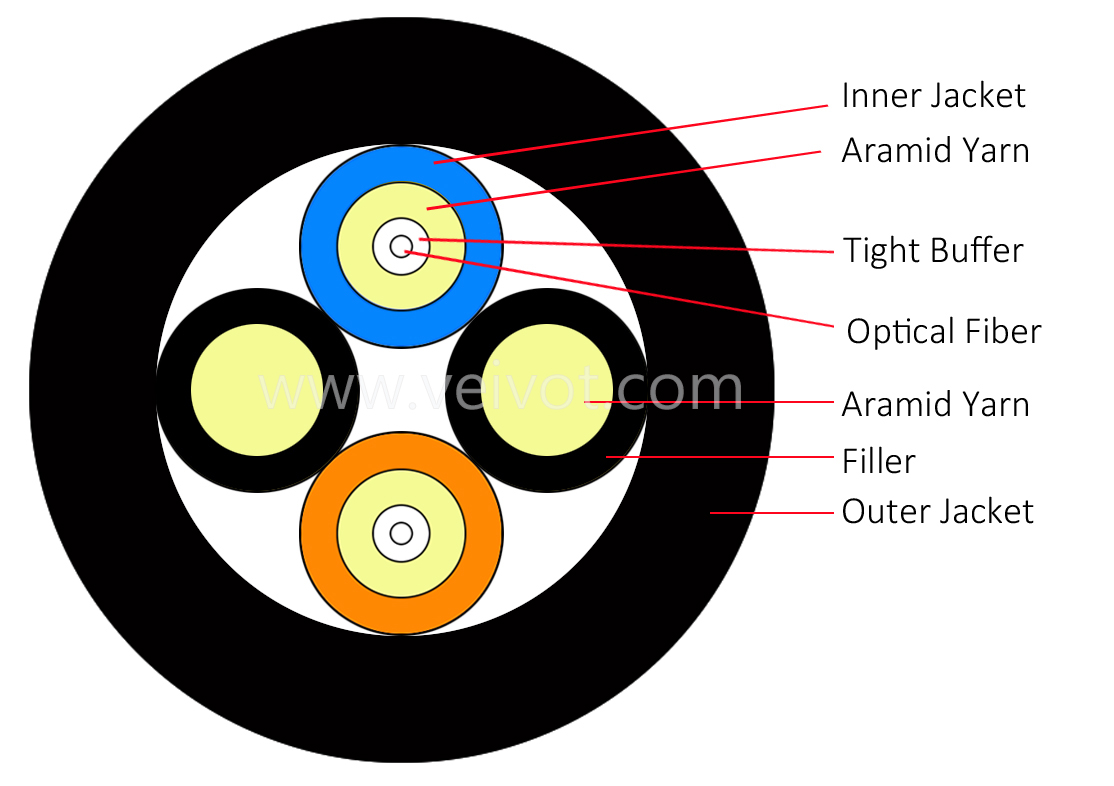

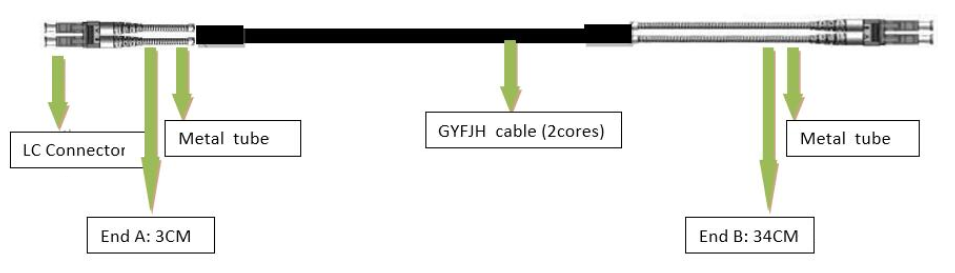

Structure parameters of optical cable

Item | Contents | Value |

Fiber | Count | 1-4 |

Tight Tube | Material | PVC/LSZH |

Color | White | |

Diameter ±0.05 | 0.85mm | |

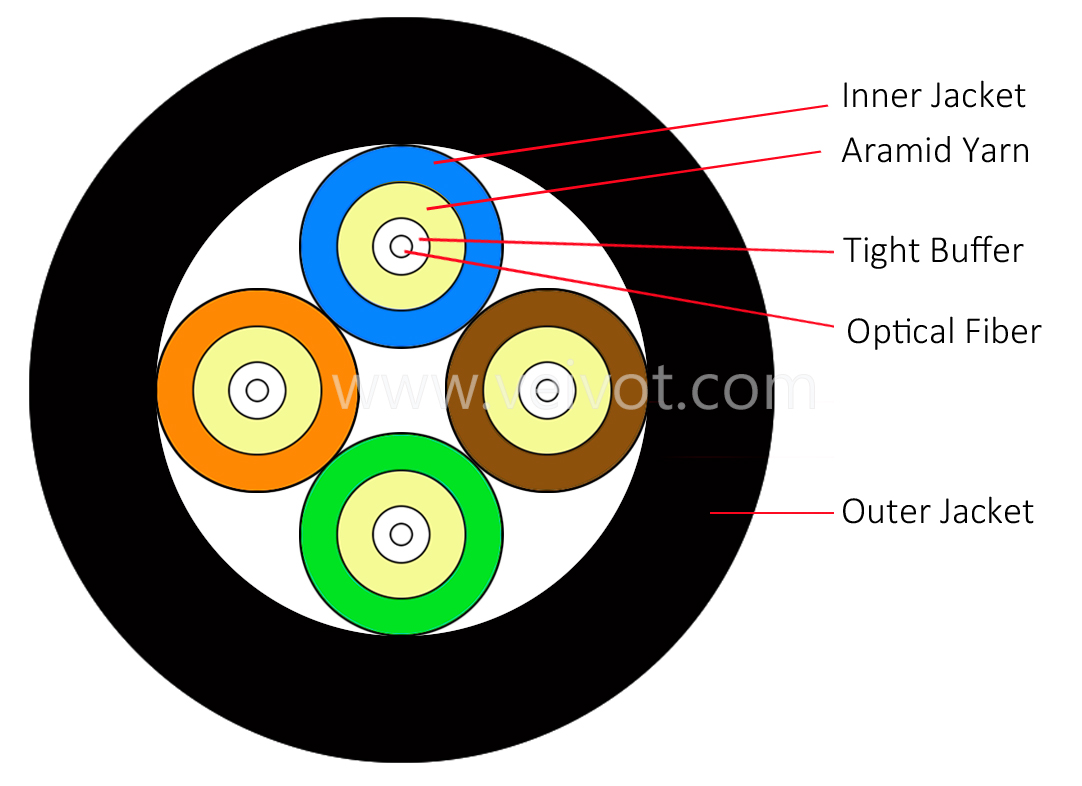

Simplex Cable | Material | LSZH |

Color | Blue,Orange,Green,Grey | |

Strength Member | Aramid Yarn | |

Diameter ±0.1 | 1.9mm | |

Filler | Material | LSZH |

Color | Black | |

Strength Member | Aramid Yarn | |

Diameter ±0.1 | 1.9mm | |

Outer Jacket | Material | LSZH |

Color | Black | |

Diameter ±0.2 | 7.0mm | |

Weight | ±10% | 47 kg/km |

Mechanical and Environment Characteristics

Max.Tensile Strength (N) | Short Term | 400 |

Long Term | 200 | |

Crush Resistance (N/100mm) | Short Term | 1000 |

Long Term | 500 | |

Min. Bending Radius (mm) | Dynamic | 20D |

Static | 10D | |

Temperature Range (℃) | Installation | -10~+50 |

Operation | -20~+60 | |

Storage | -20~+60 | |

Transport | -20~+60 |

Application

Contact

Veivot Technology Co., Ltd.

Email: sales@veivot.com

INQUIRY

INQUIRY