Description

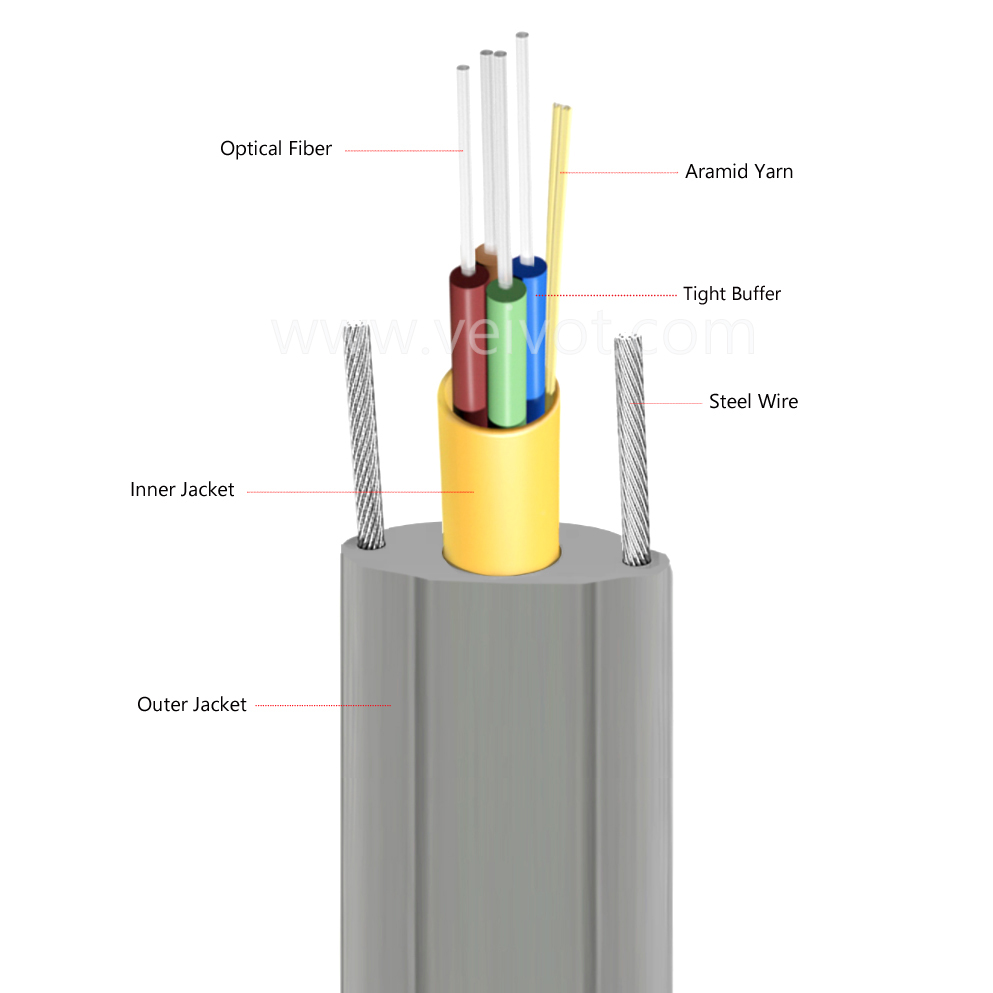

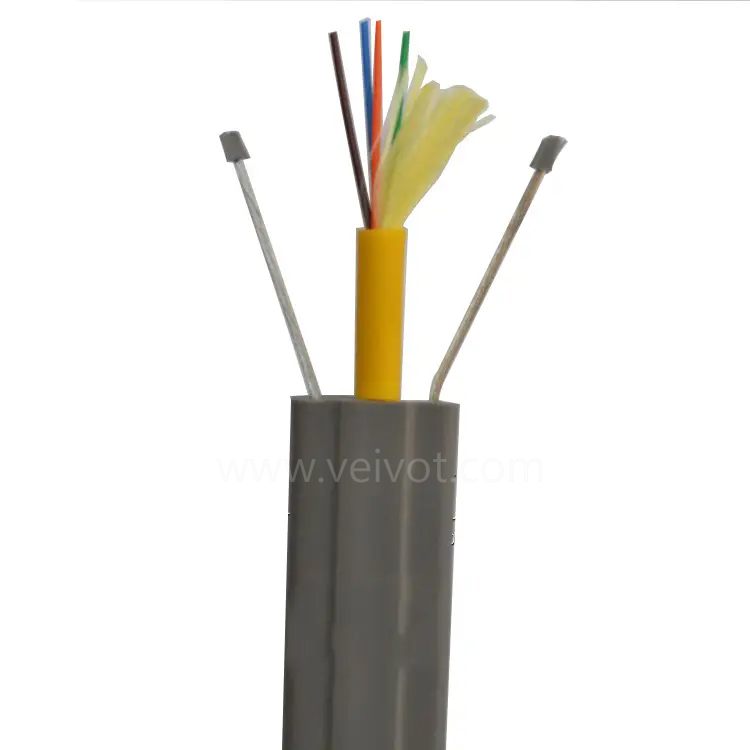

The Lift/Elevator Travelling Fiber Optical Cable uses multiple φ900 μm tight-buffered optical fibers as the optical transmission medium, and two metal wires are added as the load-bearing element of the travelling optical cable to meet the required strength of the optical cable during the travelling process and the unexpected tension during the installation process. The optical cable meets the requirements of elevators, soft and wear-resistant. It is used to connect the lift car and the motor room with high reliability. It can move up and down with the lift car to transmit data signals and monitoring signals.

The Elevator Suspension Fiber Cable is used in mobile laying applications. It is mainly used for signal transmission cable for elevator equipment in reciprocating motion for a long time. The cable is constructed with 4 Core Fibre , Steel wire giving strength to the cable and PVC/PE insulation and PVC/TPE jacket material.

Feature

Fiber Type: G652D; G657A1; G657A2; G655C; OM1; OM2; OM3; OM4; OM5

900μm tightly buffered optical fiber makes the cable easy to install;

The cable is soft and wear-resistant;

The cable has excellent bending performance and excellent bending resistance;

The outer sheath material is corrosion-resistant, UV resistant, and flame retardant;

Due to its fiber optic nature, the product is not subject to electromagnetic interference;

The processing technology is rigorous, and the design is scientific and reasonable, which can meet the requirements of high reliability, safety performance, and flame retardant performance of elevators;

Application

Suitable for connecting elevator car and motro room

Technical Parameters

Item | Contents | Value |

Count | 4 | |

Color | natural | |

Tight Buffer | Color | |

Material | PVC/LSZH | |

Nominal Diameter | 0.9mm | |

Insulation | Material | PE/PVC |

Colour | Yellow | |

Strength member | Material | Stainless steel wire |

Count | 2 | |

Outer Jacket | Material | TPE/PVC |

Color | Grey | |

Diameter ±2mm | 7*18mm | |

Working Voltage | 30V | |

Max. Tensile Strength | Short Term | 3000N |

Crush Load | Short Term | 1500 N/100mm |

Min.Bending Radius | Operation | 12D |

Installation | 30D | |

Temperature Range | Operating | -20 ~ +70℃ |

Installation | -10 ~ +50℃ | |

Flame Resistance | IEC60332-1 | |

INQUIRY

INQUIRY