What is air-blown fiber cable?

British Telecom developed the technology of installing flexible and lightweight fiber optic units using compressed air in the 1980s. This early jet technology did not require additional thrust. The real cable jet technology was invented by Willem Griffioen of KPN Research in the late 1980s. After decades of development, this technology has been successfully applied to long-distance trunk networks, metropolitan area networks and fiber access networks in Europe and the United States.

What are the characteristics of air-blown fiber cable?

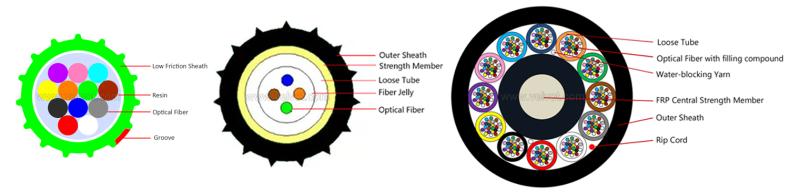

Have you ever seen a maglev train? It glides above the track with little contact with the track, thus minimizing friction. This situation is similar to air-blown fiber optics. The air-blown fiber optic system uses air to blow micro-fiber cables into pre-installed micro-ducts. The air is blown into the micro-ducts, creating a nearly frictionless surface. This air reduces the friction between the fiber optic cable jacket and the inner wall of the duct. In other words, the cable contacts the air instead of the duct, which makes installation easier and faster. The micro-ducts can be easily removed, and each micro-duct can be delivered to a different route. Using these ducts, the fiber optics can be blown, allowing for easy distribution without splicing and creating point-to-point installations.

Where is air-blown cable suitable?

Air-blown micro fiber cable systems are quickly becoming the system of choice for access networks where cost to home, speed of deployment, flexibility and future scalability are critical. Today, air-blown fiber to the home is the architecture of choice for access networks (also known as the “last mile”), delivering telecommunications services to the end-user premises.

Data Centers and 5G - Another less obvious application for blown fiber technology is in data centers, 5G or other networks that require high fiber count connections between two points. Sometimes thousands of fibers are required, and blowing multiple cables into microducts can be installed faster and more safely. It is also easier to build redundant networks.

It is important to note that QIC fiber and microducts are equally suitable for indoor and outdoor use. For indoor applications, flame-retardant microducts are typically used.

Comparison of air-blown fiber cable and traditional fiber cable

Structured cabling systems with traditional fiber optic cable have proven to be an efficient and cost-effective solution for private networks. Although air-blown fiber cable has many advantages, there are some projects where air-blown cable may not achieve the balance of cost and benefit.

One example is network growth methods. Most air-blown fiber cable installations allow for network growth. However, if most connections are already full, then the justification for air-blown fiber cable may be questionable. This is because much of the value of air-blown fiber cable is in its long-term cost reduction. Installing only what is needed today may save current costs, but not planning for future growth will offset this future benefit. If your needs are so high that you cannot afford to leave a lot of unused dark fiber, then ABF may not be the right solution.

We generally recommend air-blown cable in environments where a lot of moves, adds, and changes are expected. This can save costs compared to traditional cabling installations. However, you can never completely get rid of traditional fiber. For example, in environments where the network requires a large number of strand count trunks (i.e. 144, 288, etc.).

What are the benefits of air-blown fiber cables?

Air-blown fiber cable is installed by blowing in, rather than pulling in, which places zero tensile stress on the fiber during installation and eliminates fiber splice points, which reduces attenuation and improves system performance and integrity.

Installing air-blown fiber cable ensures that microducts can be reused in the future for fiber expansion or replacement by blowing out existing microcables and blowing in new microcables.

Air-blown fiber cable systems offer cost savings and other benefits over traditional fiber systems. These benefits include reduced outside plant materials, faster installation time, fewer fiber connection points (thus reducing the number of splices), simplified repair and maintenance, and a path for future application evolution (such as adding new fibers).

INQUIRY

INQUIRY