Brand: VEIVOT

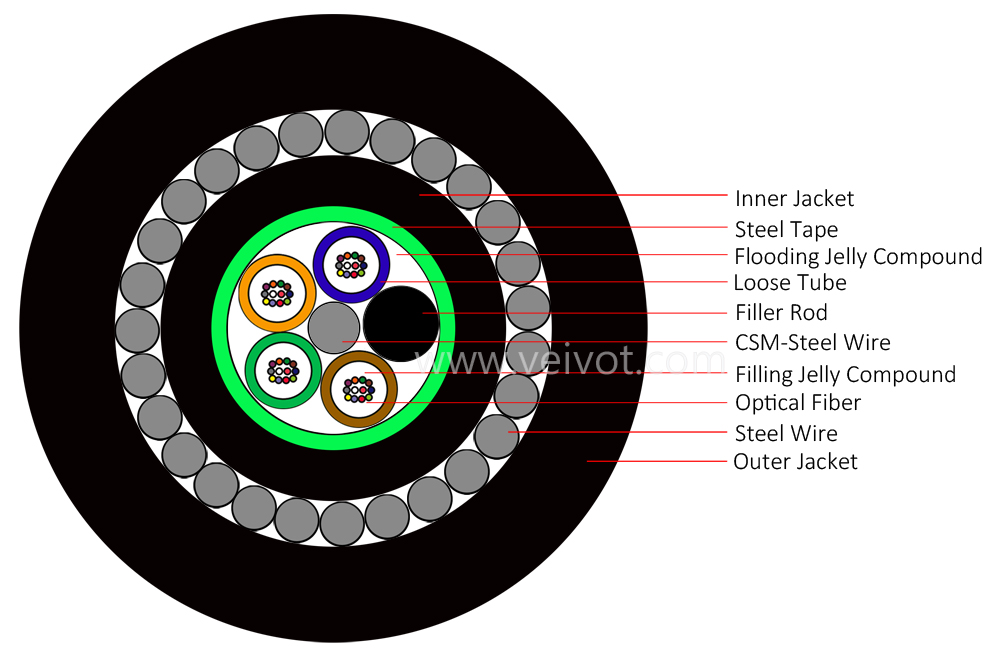

Fiber Optic Cable: GYTS33 Fiber Optic Cable

Fiber Type: G.652D or other fiber

Fiber Amount: 2-288

Application: Under-water or Direct Buried

Description

GYTS33: Stranded Loose Tubes, Steel Wire Central Strength Member, Flooding Jelly Compound, Double-Sided Plastic Coated Steel Strip (PSP), PE Inner Jacket, Multi Small Steel Wires Armoring, PE Outer Jacket.

GYTS33 cable is particularly suitable for installation in freshwater and shallow water areas. It does not require wiring and can be used for underwater wiring with short communication distances.

Features

Fiber counts: 2 ~ 288 fibers

Fiber Type: G652D; G657A1; G657A2; G657B3; G655C; OM1; OM2; OM3; OM4; OM5

Inner/Outer jacket: PE

Excellent mechanical and temperature properties are guaranteed by precise excess fibers.

The key protection of fiber is based on excellent hydrolysis resistance.

It has excellent compression resistance and flexibility.

PSP enhances the compression resistance, impact resistance, and moisture resistance of the cable.

The steel wires ensure tensile strength.

Application

Outdoor Under-water, direct buried

Transmission performance

Fiber Type | 9/125um G652D | 9/125um G655C | 62.5/125um OM1 | 50/125um OM2-OM5 |

Max. Attenuation (dB/km) | 0.36/0.22 | 0.22/0.26 | 3.5/1.5 | 3.5/1.5 |

Typical. Attenuation (dB/km) | 0.35/0.21 | 0.21/0.24 | 3.5/1.5 | 3.0/1.0 |

Structure parameters of optical cable

Fiber Count | Structure | Loose Tube | CSM | Water Blocking | Armor | Inner Jacket | Peripheral reinforcement | Outer Jacket | Diameter (mm) | Approx Weight (kg/km) |

2-30 | 1+5 | PBT | Steel Wire | Flooding Jelly Compound | Corrugated Steel Tape | PE | Steel Wires | PE | 12.8 | 278 |

32-36 | 1+6 | 13.2 | 297 | |||||||

38-60 | 1+5 | 13.9 | 328 | |||||||

62-72 | 1+6 | 14.2 | 344 | |||||||

74-84 | 1+7 | 15. 1 | 373 | |||||||

86-96 | 1+8 | 15. 8 | 397 | |||||||

98-108 | 1+9 | 16. 6 | 447 | |||||||

110-120 | 1+10 | 17. 2 | 475 | |||||||

122-132 | 1+11 | 18. 3 | 568 | |||||||

134-144 | 1+12 | 18. 9 | 593 | |||||||

146-216 | 1+6+12 | 18. 4 | 513 | |||||||

218-288 | 1+9+15 | 20. 5 | 610 |

Mechanical & Environmental Performance

Item | Contents | Unit | Parameters |

Max. Tensile Strength | Short term | N | 10000 |

Long term | N | 4000 | |

Max. Crush | Short term | N/100mm | 5000 |

Long term | N/100mm | 3000 | |

Min. Bending Radius | Operation | mm | 12.5 times of cable diameter |

Installation | mm | 25 times of cable diameter | |

Applicable Temperature Range | Operation | ℃ | -40 ~ +70 |

Installation | ℃ | -20 ~ +60 | |

Storage & Shipping | ℃ | -40 ~ +70 |

INQUIRY

INQUIRY